What does TPS stand for?

Thermoplastic styrene block copolymers (TPS)

What does TPS stand for?

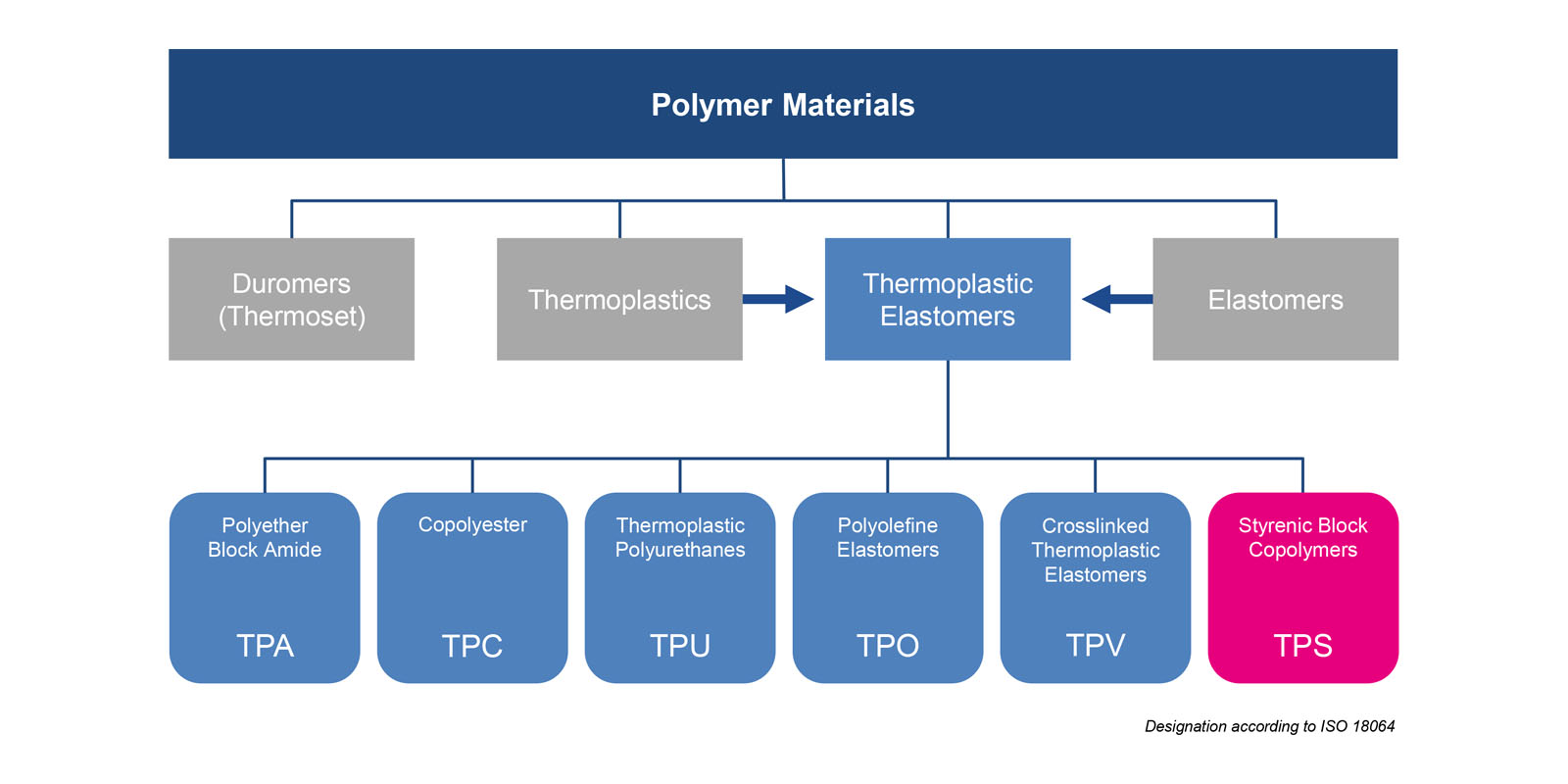

Thermoplastic styrene block copolymers, or TPS, describe a subgroup of thermoplastic elastomers (TPE).

TPS products consist of at least a triblock copolymer of styrene and a specific diene in which the two end segments are polystyrene and the inner soft segment is a polydiene or hydrogenated polydiene.

How are TPS produced?

Unlike TPA, TPC and TPU, TPS materials are not considered as reactor products. TPS are compounds - this means that manufacturers melt and homogenize various raw materials in extruder systems. In the case of TPS, different SBC polymers are mixed with thermoplastics. The uniform mixing of the thermoplastic component with the soft component (SBC) produces the typical material properties of TPS so that they can later be processed in the injection molding or extrusion process. Together with other components, such as fillers, process oils and additives, the selection and the mixing ratio determine the properties of the respective compound.

The process of blending and compounding SBC polymers with other polymeric materials and ingredients gives manufacturers almost unlimited possibilities: New formulations are developed depending on the use of the raw materials, but also depending on the mixing ratio. This diversity can even be extended: With the help of special additives and fillers, polymer blends can have properties such as electrical conductivity or even flame retardancy.

In addition, the production process itself and the conditions applied also have a significant influence on the properties of the TPS materials and their performance.

How are TPS processed?

Thermoplastic elastomers (TPE) are produced and delivered to the customer in pellet form. KRAIBURG TPE granules can be processed without the addition of other substances. There are various ways to process these. The most commonly used methods include the injection molding and extrusion processes. However, thermoplastic elastomers can also be blow molded or processed using 3D printing.

Depending on the formulation and properties, it is possible for the materials to bond to other materials through processing in multi-component injection molding, as well as co-extrusion. Products from KRAIBURG TPE form an adhesion with polypropylene (PP), polyethylene (PE) and polystyrene (PS), as well as with engineering plastics such as polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), styrene-acrylonitrile copolymer (SAN), polybutylene terephthalate (PBT), etc. Excellent adhesion results can also be achieved with polyamide, such as PA6, PA66 and PA12.

The success story of thermoplastic elastomers is largely based on the advantages of multi-component injection molding. TPE compounds can be processed like plastics, but have the properties of elastomers. This fact enables efficient processing at high volumes - especially with the multi-component technology.

Can TPS be recycled?

Due to their physical crosslinking, thermoplastic elastomers can always be melted down and returned to the processing chain. In selected applications, it is usually recommended that customers add up to 15% to the virgin material in order to recycle start-up materials and sprues.

In addition, KRAIBURG TPE is working intensively on new formulations in which recyclates are already used in the manufacturing process. The first recycling series have already been included in the portfolio and projects in the automotive and industrial sectors have been successfully implemented.

Does KRAIBURG TPE produce TPS?

Since 1985, KRAIBURG TPE has been developing and producing thermoplastic elastomers based on styrene block copolymers. Over the past decades, KRAIBURG TPE has accumulated a wide range of expertise and has been able to expand its portfolio, which consists largely of TPS materials, with a great deal of experience - always with an eye to current customer and market requirements. Tailor-made and with precision, the company adapts products to the specific requirements of the customers.

Thanks to the strong market orientation and special market teams, KRAIBURG TPE develops and produces high-quality compounds worldwide for the automotive sector, for industrial and consumer applications. KRAIBURG TPE also offer a portfolio with comprehensive approvals for the highly sensitive medical and pharmaceutical markets.

Thermoplastic Elastomer (TPE)

Thermoplastic Polyurethane (TPU)

Thermoplastic polyester elastomers (TPC)

Thermoplastic vulcanizates (TPV)

Thermoplastic polyamide elastomers (TPA)

Thermoplastic polyolefins (TPO)